What is a Set Screw and How Does It Work?

A set screw, also known as a grub screw, is a type of fastening device used widely in mechanical and industrial settings. Unlike traditional bolts, set screws do not require a nut to secure objects together. Instead, they are designed to pass through one object and be tightened against another, creating a firm hold. This unique feature makes set screws indispensable for applications where space constraints or specific design requirements preclude the use of a nut.

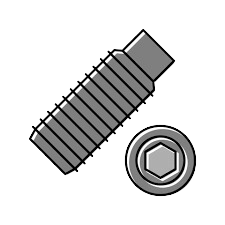

Set screws come in various types, each tailored for specific needs. The standard set screw is typically characterized by a hexagonal or slotted head, which allows for easy adjustment using common tools such as Allen wrenches or screwdrivers. Another common variant is the grub screw, which is headless and often used in applications where a flush fit is necessary. This type of set screw is turned entirely within the threaded hole, making it ideal for situations where protruding heads could interfere with the overall design or operation of the machinery.

The primary function of a set screw is to secure an object within or against another object by applying a clamping force. This is achieved through the internal threading of the screw and the application of torque during installation. When a set screw is tightened, its threads engage with the internal threads of the hole, creating friction that holds the screw in place. In many cases, the tip of the set screw may dig into the surface of the secured object, adding an additional layer of grip. This is particularly useful in scenarios where vibration or movement could otherwise cause loosening.

Set screws are commonly used in a variety of applications, ranging from securing gears and pulleys on shafts to holding components in electronic devices. Their versatility and ability to provide a reliable hold without the need for additional hardware make them a popular choice in numerous industries. Whether it’s the standard set screw or the more specialized grub screw, understanding their function and proper use is essential for ensuring the stability and efficiency of mechanical assemblies.

Specialty Set Screws: Nylon Tip and Brass Tip Variants

When selecting the appropriate set screw for a specific application, considering specialty variants such as nylon tip and brass tip set screws can provide significant advantages. These types of set screws are designed to address specific requirements, enhancing both performance and longevity in various settings.

Nylon tip set screws are distinguished by their unique nylon tips, which offer several notable benefits. A primary feature is their ability to reduce vibrations, making them particularly useful in environments where stability is crucial. The nylon tip also provides a gentler grip on softer materials, reducing the likelihood of damage when securing components. This characteristic makes nylon tip set screws ideal for applications involving delicate materials or high-vibration environments, such as in precision instruments or electronic devices.

On the other hand, brass tip set screws are renowned for their superior corrosion resistance and conductivity. Brass is inherently resistant to rust and tarnish, which ensures the longevity and reliability of the screw in corrosive environments. Additionally, the excellent electrical conductivity of brass makes these set screws particularly suitable for use in electrical components and assemblies. Typical applications for brass tip set screws include securing parts in marine equipment, automotive components, and electrical systems where both corrosion resistance and conductivity are paramount.

When comparing nylon tip and brass tip set screws, it is essential to weigh their respective benefits and potential drawbacks. Nylon tip set screws are advantageous in reducing wear and preventing damage to softer materials, but they may not offer the same level of durability in harsh environments as brass tip set screws. Conversely, while brass tip set screws provide excellent corrosion resistance and electrical conductivity, they might not be as effective in minimizing vibrations or protecting delicate surfaces.

Understanding the unique features and applications of nylon tip and brass tip set screws enables users to make informed decisions based on their specific needs, ensuring optimal performance and longevity of their assemblies.