What is a Set Screw and Its Various Types

A set screw, commonly referred to as a grub screw, is a specialized fastener primarily employed to secure one object within or against another without the need for a nut. These screws are integral to machinery, where they function to prevent relative movement between two parts, ensuring stability and precision in mechanical operations. The defining characteristic of set screws is their ability to establish a firm fix through the application of pressure, often without protruding from the surface of the components they join.

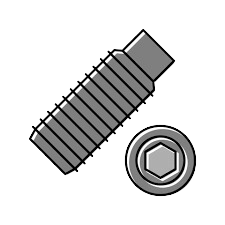

Typically, set screws are headless, featuring a hex socket drive that allows for easy installation and removal using an Allen wrench. This design ensures that the screw remains flush or below the surface of the material, reducing the risk of interference or snagging. The versatility of set screws makes them suitable for a wide range of applications, from securing gears and pulleys on shafts to fixing collars and bearings in place.

Various types of set screws are available, each tailored to specific requirements and conditions. The standard grub screw is the most common, characterized by its headless design and hex socket drive. However, other types include cup point, flat point, cone point, and knurled cup point set screws, each offering distinct advantages based on the application. For example, cup point set screws provide excellent resistance to vibration due to their concave tip, while flat point set screws are ideal for applications requiring frequent adjustments, as they cause minimal surface damage.

The material composition of set screws is also critical, influencing their performance and suitability for different environments. Common materials include stainless steel, alloy steel, and brass. Stainless steel set screws are prized for their corrosion resistance, making them suitable for harsh environments. Alloy steel set screws offer superior strength and durability, while brass set screws are often used in applications where electrical conductivity and corrosion resistance are paramount.

Understanding the various types of set screws and their specific functions sets the stage for a deeper exploration of specialized variants such as nylon tip set screws and brass tip set screws, which offer unique benefits for particular applications.

Specialized Set Screws: Nylon Tip and Brass Tip Set Screws

Nylon tip set screws are distinguished by their unique construction, featuring a nylon tip that offers significant advantages in specific applications. One of the primary benefits of nylon tip set screws is their ability to minimize damage to the surfaces they secure. This is particularly valuable in situations where the integrity of the material is paramount. The nylon tip acts as a cushion, distributing the clamping force more evenly and reducing the risk of surface indentation or deformation.

Another notable advantage of nylon tip set screws is their anti-vibration properties. The nylon material can absorb vibrations, preventing the screw from loosening over time. This makes them an excellent choice for applications involving moving machinery or environments subject to consistent vibrations. Common use cases for nylon tip set screws include electronics, where they secure delicate components without causing damage, and in precision machinery, where maintaining the exact positioning of parts is critical.

In contrast, brass tip set screws offer a different set of benefits, primarily due to the properties of brass. Brass is a soft metal, which means that brass tip set screws are less likely to mar or scratch the surfaces they contact. This non-marring property is particularly advantageous in applications involving delicate materials, such as in optical equipment or fine instrumentation. Additionally, brass exhibits excellent electrical conductivity, making brass tip set screws ideal for use in electrical and electronic applications where maintaining a reliable electrical connection is essential.

When comparing the performance of these specialized set screws to standard set screws, it becomes clear that each type has its specific advantages. Standard set screws, typically made of steel or stainless steel, offer robust holding power but can damage sensitive surfaces and may not perform well in high-vibration environments. In contrast, nylon tip set screws and brass tip set screws provide targeted benefits that make them indispensable in certain scenarios. Understanding the unique properties and appropriate use cases for each type ensures the selection of the most suitable set screw for any given application.