What Are Set Screws and Grub Screws?

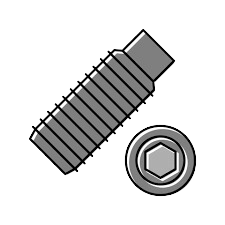

Set screws, also known as grub screws, are a type of fastener used to secure objects within or against another object. Unlike traditional screws that typically have a head, set screws are designed to be headless, allowing them to sit flush or below the surface of the material they secure. This unique feature is particularly advantageous in applications where a protruding head would be problematic or aesthetically undesirable.

The primary purpose of set screws is to exert pressure and hold objects in place. They achieve this by threading into a tapped hole and pressing the tip against the secured object. This creates a strong, friction-based hold, eliminating the need for additional components like nuts. Set screws come in various tip styles, including flat, cone, and cup points, each designed to suit specific applications and materials.

Grub screws, a subset of set screws, are distinguished by their completely headless design. This makes them especially useful in confined spaces where a traditional screw head would not fit. The headless feature also allows for a cleaner appearance, which can be essential in applications where the screw will be visible.

Set screws and grub screws are commonly used in a wide range of settings, from industrial machinery to home maintenance. In industrial applications, they play a crucial role in securing gears, pulleys, and other components on shafts, ensuring the smooth operation of mechanical systems. In home settings, they are frequently employed in securing door handles, light fixtures, and various DIY projects.

Overall, the versatility and reliability of set screws make them an indispensable component in both professional and amateur applications. Their ability to provide a secure hold without the need for additional hardware simplifies many fastening tasks, contributing to their widespread use across multiple industries.

Specialty Set Screws: Nylon Tip and Brass Tip Set Screws

Specialty set screws, such as nylon tip and brass tip set screws, offer unique features that make them ideal for specific applications. These variants are designed to address particular needs that standard set screws may not fulfill effectively.

The nylon tip set screw is engineered to reduce wear and prevent marring on softer surfaces. This makes it an excellent choice for applications involving delicate materials. For instance, when securing components made of aluminum or plastic, the nylon tip minimizes damage and ensures a secure fit without compromising the integrity of the material. Additionally, the nylon’s inherent flexibility allows for better grip and vibration resistance, making it suitable for use in precision instruments and delicate machinery where maintaining the surface finish is crucial.

On the other hand, brass tip set screws are lauded for their excellent electrical conductivity and corrosion resistance. These features make brass tip set screws particularly valuable in electrical and electronic applications. For example, in environments where non-magnetic properties are essential, such as in certain medical devices or sensitive electronic equipment, brass tip set screws provide a reliable fastening solution without interfering with electronic signals. Their corrosion resistance further enhances their durability in harsh or corrosive environments, ensuring long-term performance and reliability.

When comparing these specialty set screws to regular ones, the advantages become evident. Standard set screws, while versatile, may not offer the specific benefits needed for specialized tasks. Nylon tip set screws prevent surface damage and provide superior grip on softer materials, whereas brass tip set screws ensure conductivity and corrosion resistance in applications requiring such properties.

Practical scenarios illustrating their use include securing delicate instrumentation, where nylon tips protect the surface finish, and in electrical assemblies, where brass tips offer non-magnetic fastening solutions. By understanding the unique features and benefits of nylon and brass tip set screws, one can make informed decisions tailored to specific requirements, ensuring optimal performance and longevity in various applications.