Introduction to Set Screws

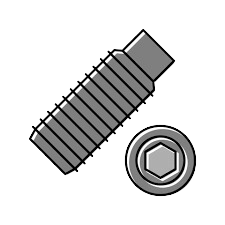

Set screws, also known as grub screws, are a type of fastener that plays a crucial role in various mechanical assemblies. Unlike other fasteners, such as bolts or screws that require a nut, set screws are designed to secure one object within or against another without the need for additional components. This unique characteristic makes them indispensable in numerous applications, particularly where space constraints or specific mechanical functions are involved.

Set screws come in a variety of types, each tailored to suit different requirements. The most common types include cup point, flat point, cone point, and dog point set screws. Each type features a distinct tip design that influences its holding power and suitability for different materials and applications. For instance, cup point set screws are known for their ability to provide a secure grip, while flat point set screws are ideal for applications where minimal surface damage is desired.

The primary function of set screws is to lock or position components securely. They are typically used in machinery to fix gears, pulleys, and other components onto shafts, preventing any relative movement. In electronics, set screws are essential for securing connectors and components in place, ensuring stable electrical connections. The automotive industry also relies heavily on set screws for tasks such as securing knobs, levers, and other controls.

One of the key advantages of set screws is their ability to provide a secure fastening solution without protruding from the surface, making them ideal for applications where a flush fit is necessary. This characteristic not only contributes to the aesthetic appeal of the final product but also reduces the risk of accidents and damage caused by exposed fasteners.

Overall, set screws are a versatile and indispensable component in various industries. Their unique design and functionality allow them to provide reliable and efficient fastening solutions in a wide range of applications, from heavy machinery to delicate electronic devices.

Specialized Types of Set Screws: Nylon Tip and Brass Tip Set Screws

Set screws are essential fasteners used to secure objects within or against another object without the need for a nut. While standard set screws can handle a variety of tasks, specialized types such as nylon tip and brass tip set screws offer distinct advantages for particular applications. These specialized set screws are designed to meet specific requirements where traditional set screws may fall short.

Nylon tip set screws are distinguished by their nylon-tipped ends. This feature provides a secure hold without damaging the surface it contacts. The nylon material is softer than metal, allowing it to cushion the contact point and distribute the pressure evenly. This characteristic makes nylon tip set screws particularly useful in delicate instrumentation and assemblies where surface integrity is paramount. Additionally, the nylon tip provides excellent resistance to vibration, ensuring that the set screw remains in place even in dynamic environments.

Brass tip set screws, on the other hand, are equipped with brass-tipped ends. Brass, being a softer metal, offers non-marring characteristics that make these set screws ideal for use with softer materials like aluminum, copper, and certain plastics. Brass tip set screws are frequently used in applications where preserving the surface finish is crucial, such as in soft metal assemblies and plastic components. Moreover, brass provides inherent corrosion resistance, making these screws suitable for environments where exposure to moisture or other corrosive elements is a concern.

The specialized nature of nylon tip and brass tip set screws makes them invaluable in various applications. For instance, they are often employed in the assembly of delicate instrumentation, where precision and surface integrity are critical. They are also beneficial in plastic assemblies and soft metal applications, where traditional set screws might cause damage. The added benefits of reduced vibration and corrosion resistance further enhance the utility of these specialized set screws, making them a preferred choice in many industrial and mechanical settings.